Have you ever had a roofer tell you your roof was installed incorrectly? Have you ever had a shingle fall off your roof, but your roof is less than 15 years old? How can a roof be installed incorrectly, and how can a roofer determine that?

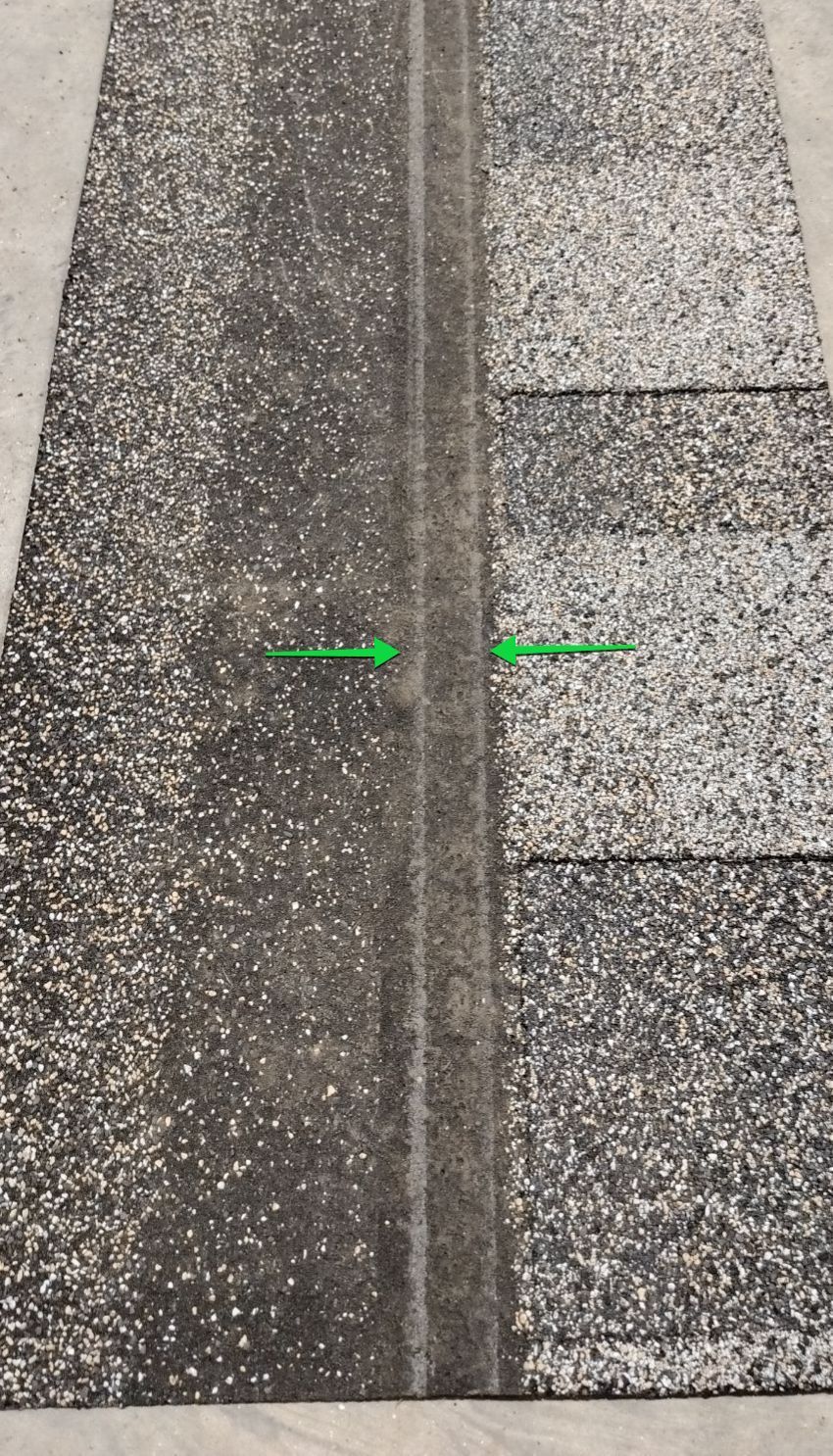

To answer that, let's talk first about how a shingle is created. Modern architectural shingles (shown here),

are made of two fiberglass mats laminated together. You can check out this article here to learn more details about what goes into a shingle, but for now, you just need to know that an architectural shingle is made of two pieces, laminated together along a horizontal line. This line is at the midpoint. Here is a side view of a shingle showing that overlap.

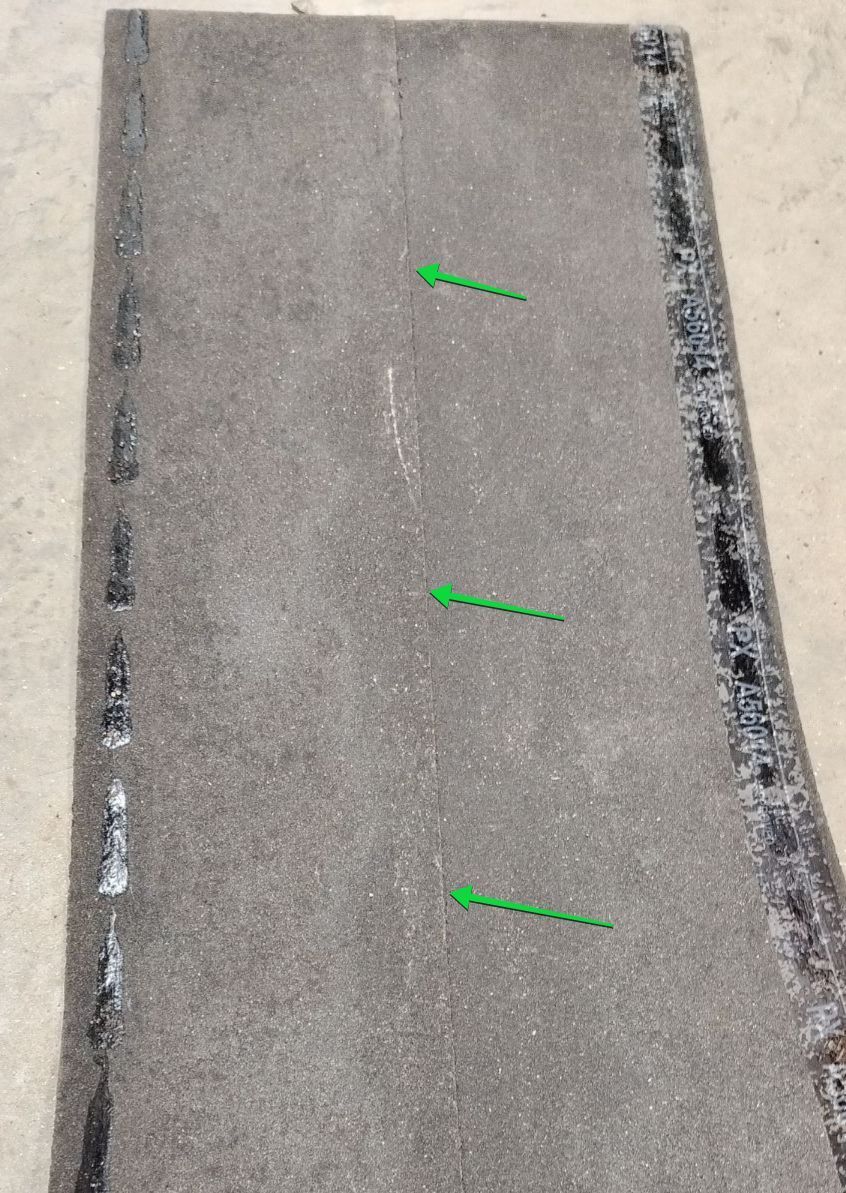

Here is a view of the shingle from the back:

Ok, so why is this important?

This laminated seam is the strongest part of the shingle. Manufacturers designate this area as the “Nail Zone” and recommend that all nails be driven through it. The nail zone is clearly marked by a visible line on every shingle. To ensure proper roof strength and maintain your manufacturer’s warranty, nails must be installed along this strip.

Here is an example of a shingle that was not properly installed. I marked a line in white showing the nail zone. I circled the actual nail locations in red. This is a real example of a shingle that fell off a roof. You can see that the nails clearly missed the mark.

Ok, so I hired a professional roofer and spent a ton of money. What the heck happened?

Great question.

The short answer? It depends.

If the problem is widespread—say, more than half the roof—then it’s a sign the roofer didn’t prioritize training or quality. In some cases, they may have hired a crew without proper vetting and failed to supervise the job. If the issue is limited to a small section, it usually points to a lack of training for one individual worker. There’s also a third possibility: environmental and human factors. Extreme heat, exhaustion, or a crew rushing to finish before the day ends can all lead to mistakes.

This shouldn’t surprise you—it gets extremely hot on a roof in summer. The surface temperature can easily exceed 150°F, which is like working inside a sauna all day! Add direct sun exposure, and you’ve got a tough environment. Now consider the pace: most roofing jobs start early and aim to finish the same day. Crews work long hours, day after day, in these conditions. Shingles are heavy, tools are heavy, and fatigue sets in quickly. Under those circumstances, mistakes happen. That’s why you might see a few shingles nailed incorrectly—sometimes just one or two scattered around the roof, or a small section where nails missed the mark.

So, what can I do about it?

That’s a great question. The truth is, the damage is already done—and hopefully your roof is sealed tight. A full-scale investigation isn’t practical because it would mean breaking the seal between shingles, which could weaken the roof even more. Instead, a roofer can start with a spot check in different areas to assess quality. Based on what they find, they might recommend adding nails and resealing, or replacing a small section. If the problem is severe, a full replacement may be necessary. In general, a high-nailed roof isn’t guaranteed to fail, but it does increase the risk. Factors like roof pitch, local wind speeds, and snow accumulation can make failure happen sooner, so keep that in mind before making any big decisions.

For your next roof, choose a roofer who values transparency and quality. Look for someone who explains their installation process, provides training for their crew, and supervises the job on-site. A well-established company will also have the flexibility to extend the project into an extra day if needed to ensure proper installation. If the sun is setting, the heat is extreme, or you notice quality and safety slipping, speak up. A good company will listen and adjust. I hope you don’t need a roof for a very long time! On average, most homeowners replace only one roof in their lifetimes.

Is there anything else I can do?

Yes, absolutely. Materials matter here. Sexton Roofing and Siding installs IKO Shingles. The IKO Dynasty shingle provides an extra wide, reinforced nail strip. Check it out here:

This extra wide nailing strip ensures that every nail hits the mark. This strip not only prevents high-nailing, but also adds extra protection against wind uplift, and extra peace-of-mind on those steep sloped roofs.

For more information on our installation process,

contact us or give us a call, 413-534-1234.

Bonus question: In one of the pictures shown above, there are nail holes at the top of the shingle too. What is that all about? Is that extra protection? Is it better or worse?

Good catch. It’s actually not better or worse. Those nail holes are from the shingle that was installed

above that shingle. The nailing strip of the overlapping shingle will cover the top part of the shingle below it.