Have you ever wondered what an asphalt shingle is actually made of? No? Come on, just play along for a moment. You might be surprised by how helpful this is, especially when you’re talking to a roofer or trying to make decisions for your own home project. Who knows, maybe you’ll become a roofing expert one day! (Okay… probably not. But you will feel a lot more confident after this.)

Let’s take a quick look at what goes into a typical architectural asphalt shingle. Each layer plays an important role:

- A fiberglass mat

- An asphalt coating

- Protective granules

- A sealant strip

Now let’s break it down in a way that actually makes sense.

1. The Core: Fiberglass Mat

At the heart of the shingle is the fiberglass mat—the foundation everything else attaches to. Think of it like the shingle’s skeleton. It gives the shingle its shape, strength, and flexibility so it can handle wind, movement, and the changing seasons.

But while the fiberglass mat is strong, it can’t stop water on its own. That brings us to the next, and arguably most important, layer.

2. The Waterproofing: Asphalt Coating

The fiberglass mat is coated with asphalt on both sides, creating a sort of asphalt “sandwich.” This is the true workhorse of the shingle. Asphalt delivers the waterproofing, protects against hail and debris, and holds everything else together.

If the fiberglass is the skeleton, asphalt is the muscle.

The only downside? Asphalt ages. Sunlight (especially UV rays) slowly breaks down the chemical binders, and daily temperature swings cause expansion and contraction. Over time, that leads to cracking. Fortunately, the next layer helps protect it.

3. UV Protection & Color: Granules

Those colorful little granules on the surface aren’t just for looks. They’re crushed stone coated with ceramic pigments, and they act like sunscreen for the asphalt underneath. They absorb and deflect UV rays, dramatically slowing down the aging process.

As a bonus, they give shingles their color. If you’ve ever cleaned your gutters and noticed those little rocks collecting at the bottom, those are the granules doing their thing.

4. The Sealant Strip

On the underside of each shingle is a small strip of black sealant. It may look insignificant, but it’s one of the most important parts of the system. Once installed and warmed by the sun, this strip bonds the shingles together, helps seal the nails below, and creates a watertight, wind‑resistant layer.

Small strip, huge impact.

Here is a photo from the IKO website, www.iko.com

5. How the Shingle Is Formed

An architectural shingle isn’t just one piece—it’s actually two pieces laminated together. The top portion includes the “dragon’s teeth” (those cutout shapes you see from the ground), plus an unseen upper section. This forms most of the visible shingle.

Attached behind that is the lower portion, which adds thickness, dimension, and strength. Together, these pieces create a heavier, more robust shingle than the old 3‑tab style. During manufacturing, high heat fuses the two sections together. This lamination creates a strong bond and gives the final product that thicker, dimensional look that homeowners prefer today.

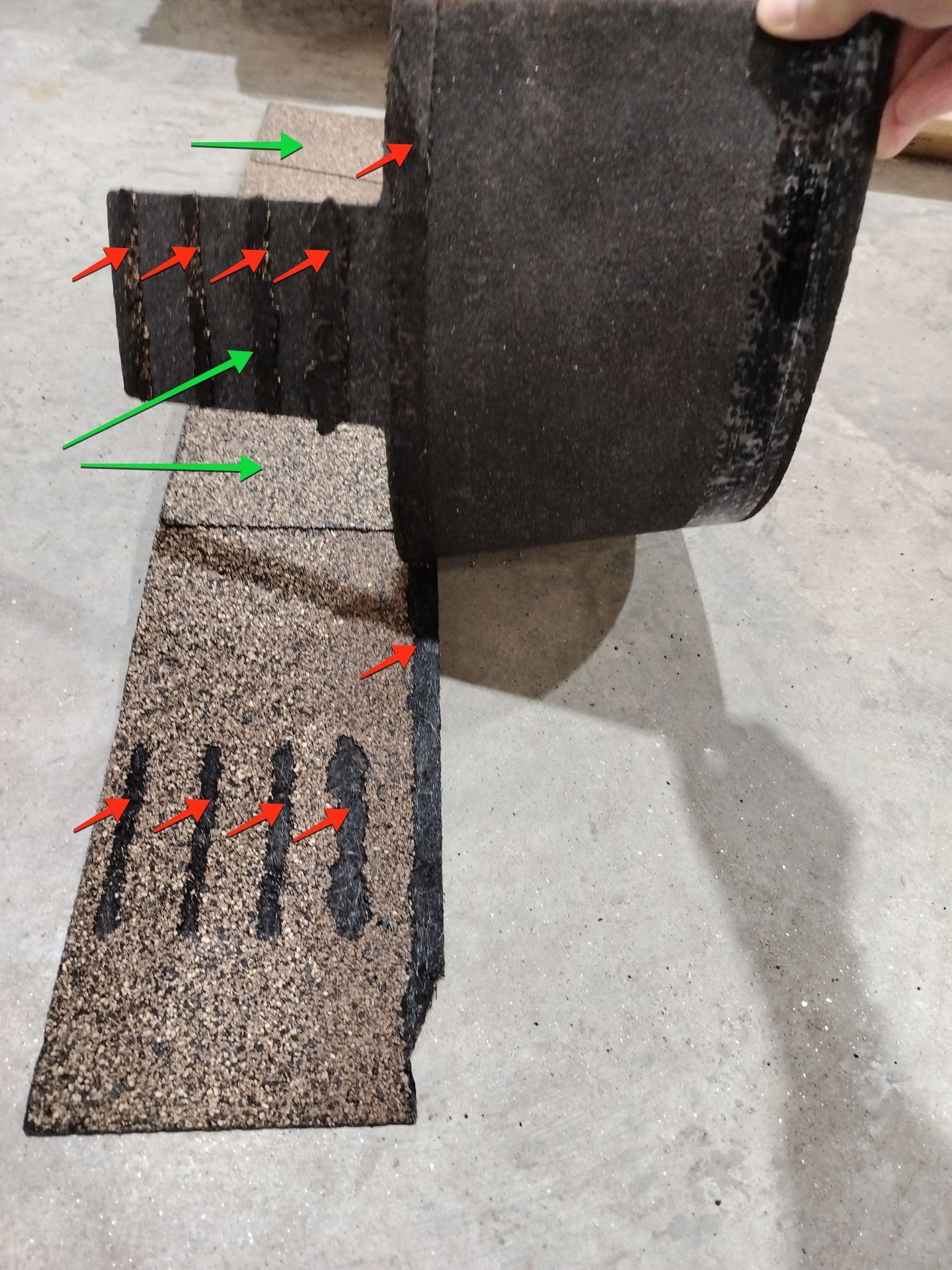

Take a look at this photo here to see the pieces partially pulled apart. Notice the red arrows pointing to all the locations where the lamination occurs. The green arrows point to the dragon's teeth, both the back and the front.

6. Why Architectural Shingles Win

The result is a shingle that’s heavier, tougher, and far more wind‑resistant than the classic 3‑tab shingles. In fact, 3‑tabs are so outdated that many Northeast suppliers barely carry them anymore—and even when they do, you’ll only find a couple of color options.

Some people still ask about 3‑tabs because they assume they’re cheaper. But that’s mostly a myth. Since manufacturers hardly produce them, the cost gap has become surprisingly small. Almost every plant now focuses on architectural shingles because they last longer, look better, and use more advanced materials.

When you put all that together, strength, lifespan, look, and price, it’s clear: choosing architectural shingles isn’t just the better option…it’s the obvious one.

Contact us today.